Triangle Defense - China’s PCC

I first learned about Triangle Defense (SZ 300775) when it announced it signed an agreement with Siemens energy to supply gas-turbine parts. The markets overjoyed and pumped 20% on the news, and judging from the turnover rate it has basically rotated to a new set of shareholders. In my previous post about the “three musketeers of gas turbines,” I mentioned that Triangle Defense is still primarily a military-industry company—military accounts for roughly 80% of the investment value. So the investment logic is still “military first, gas turbines second.” That’s why I think it’s necessary to study Triangle’s defense and other businesses in greater depth. Because military orders are opaque and confidential, we can only infer a few things from financial reports and official announcements.

I view Triangle Defense as China’s core supplier of high-end forgings for aerospace. It is transforming from a supplier of mainly military “blank forgings” into a comprehensive high-end precision-manufacturing platform spanning military aircraft, commercial aircraft, gas turbines, and space. I’ve ranked what I see as the four key growth engines by importance.

1. Core Growth Engine #1: 1250MN Project — Ultra-large Component Manufacturing With National Strategic Asset Status

This project sits under SanChong Aviation. Triangle is the technical provider and operator, holding a 43.3% stake; the remaining equity is held by local state-owned capital, which is also a major shareholder of Triangle. Triangle has significant influence over SanChong and consolidates its financials. The project is highly valued locally—Xi’an’s mayor and provincial leaders attended the groundbreaking ceremony, aiming to build a “major aviation industrial park.” Yanliang District (Aviation Base) has strong foundations in aircraft structural manufacturing, aviation materials R&D, and aircraft assembly. Completion is expected by the end of 2026.

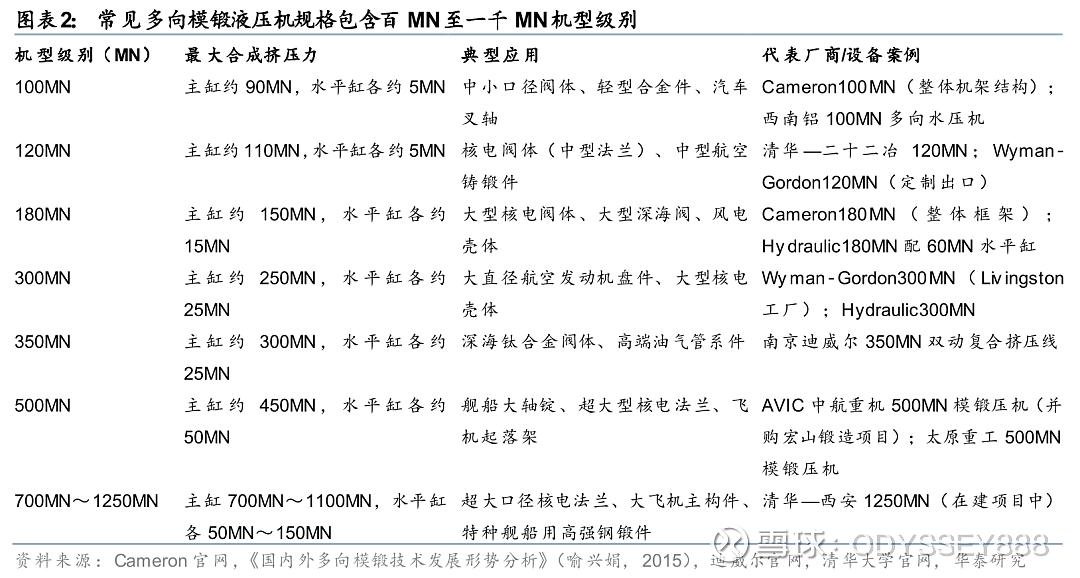

The current 1250MN, or 12,500-ton, multi-directional forging hydraulic press represents the full "generational leap" compared to the previously commissioned 400MN forging press. If the 400MN press brought autonomous control for Chinese PLA, the 1250MN one positions Triangle at the global frontier-something that is not rivaled anywhere else.

Strategic Implications & Market Potential

This 400MN equipment is a major driver of the company's dominance in next-generation military aircraft large-structure forgings, holding a market share of over 50%. The 1250MN project will be the company's "winning move."

Extremely high technical barriers.

Multi-directional forging uses multi-cylinder synchronous control to form complex, hollow, multi-branch structures in a single heating and stroke. Its equipment (ultra-large multi-directional press), processes (complex metal-flow control), and materials (hard-to-deform alloys) form a deep moat. Triangle is the only company globally to master these technologies.

Large market potential:

This aligns with global upgrades in high-end industrial equipment. In aerospace, it meets demand for integrated large rocket and commercial-space structures; in deep-sea equipment, for high-pressure, corrosion-resistant valves and components; in clean energy, for next-generation nuclear-power pressure vessels and ultra-supercritical thermal-power components, and potentially fusion-reactor forgings. The global forging market is projected to reach USD 199.69B by 2034 (CAGR 7.7%), with China growing even faster (CAGR 11.3%). Multi-directional forging sits at the most advanced end.

After the 400MN press succeeded, Triangle achieved near-monopoly status in high-end military forgings and maintained high margins for years. The 1250MN project will further cement its industry leadership, bind it closely to next-generation military aircraft, and extend it into nuclear power, deep-sea equipment, and other emerging sectors—making it the most important growth driver.

2. Core Growth Engine #2: The 300MN Isothermal Forging Line — Entering the “Heart” of Aircraft Engines and Gas Turbines

If the 1250MN project targets "ultra-large", then the 300MN isothermal forging line targets "ultra-precise", aimed at core hot-section components of aircraft engines and gas turbines.

Technical distinctiveness:

Isothermal forging keeps the die and billet at equal high temperatures and applies pressure very slowly. This solves cracking and incomplete filling problems common in forging titanium alloys and nickel-based superalloys. It is ideal for complex, thin-walled, and highly precise turbine disks, compressor disks, and precision blades.

Progress & Significance:

According to the company, a key forging device in its “aircraft-engine blade precision forging project” completed hot-load testing in March 2025. This means the company has initially established process capability for high-end disk/blade parts—laying the foundation for programs such as the WS-15 engine and international gas-turbine blade orders. Combined with Triangle’s existing disk-forging strengths, this forms a complete “disk + blade” engine component capability—critical for entering the core power-system market.

I think it is because it is expanding from structural components-fuselage, landing gear-into core engine forgings that have much higher margins and are in very strong demand.

3. Core Growth Engine #3: Gas-Turbine Partnerships - A “Golden Window” in Global Energy Transition

As global energy systems shift toward cleaner, more efficient power, gas-turbine demand is surging while international supply chains remain tight—creating a historic opportunity for Chinese suppliers. As I mentioned previously, only a handful of Chinese companies supply Siemens, GE-V, etc. This supply chain is promising for the long term. As order volumes become clearer next year, the company’s voluntary disclosures of orders could trigger a rerating. Gas-turbine business is not yet priced into the valuation.

Synergy and potential:

The company primarily supplies superalloy disks and large structural components for gas turbines. Its 300MN isothermal-forging capability is ideal for turbine disks and blades. This cooperation not only adds a new profit engine (gas-turbine margins may be more than 40%), but also exposes the company to world-class quality and certification systems-enhancing overall competitiveness. Though current agreements are at the framework level, orders will follow step by step after certification, opening a long-term growth channel.

4. Core Growth Engine #4: C919 Airliner Supply — Strategic Leap Downstream in the Value Chain

The company has stretched further in high-value downstream sections, deeply bound to the Chinese large aircraft program, and formed the "forging + machining + assembly" capability loop.

Skin mirror-milling (technology upgrade):

Triangle is building Asia’s leading mirror-milling line for aircraft skins. Compared with traditional chemical milling (polluting, low precision), mirror milling is a green, high-precision (±0.1mm) process. It lets Triangle supply high-end skin parts for the C919 and replaces outdated processes. Analysts estimate the market for military aircraft skin machining during the 14th Five-Year Plan at ~44.1B RMB. This moves Triangle from a forging supplier into a complex-shape component manufacturer.

Lingang fuselage assembly base:

Triangle set up a mid-aft fuselage assembly line in Shanghai Lingang, next to COMAC’s final-assembly center. This “close-to-customer” layout elevates it from forging blanks to providing fuselage-section assembly. The value per aircraft jumps from millions to tens of millions of RMB.

The real mass production of C919/C929 will probably occur after 2027–2028 due to supply-chain and certification bottlenecks, but the direction is correct—like domestic semiconductors, high-end manufacturing must be conquered eventually; early positioning will be advantageous.

5. Logic of Investment, Risks, and Summary

Core investment logics

1. Equipment gap as core moat:

The cluster of 400MN, 300MN, and 1250MN presses is world-class, thus irreproducible-a hard-technology moat.

2. Multi-curve growth, including explosive potential:

Military remains the base; the expansion of the C919 industrial-chain provides medium-term support; while 1250MN unlocks aerospace, deep-sea, and nuclear markets, gas turbines add a new international growth leg.

3. Military-industry cycle turning:

After booming from 2020–2022, the sector cooled from 2023–2025. I believe the next major upcycle (15th Five-Year Plan) begins around March next year. Q3 data already shows signs of a rebound, and confirmation next year could attract capital back.

4. Management quality:

Excellent leadership. Chairman is Shaanxi's richest individual, wife chairs Giant Bio. He follows an academic/technical track, collaborates with Tsinghua and brought in state capital. Their upstream/downstream layout is forward-looking and focuses on high-margin core business.

Sidebar: Buffett’s Acquisition of PCC

Buffett bought PCC in 2015 at ~25× PE—essentially investing in a business model with “deep moats in high-end manufacturing, low cyclicality, and sustained cash flow.” Triangle Defense is similar to this model but follows a China-specific path: Similarities: Both have formidable equipment/technology moats - Triangle's forging presses vs. PCC's precision casting. Both have a strategy of long-term binding with giant customers: PCC with Boeing/GE, Triangle with AVIC/COMAC.

Differences: PCC expanded through international M&A. On the contrary, Triangle grows organically and through industrial-chain extension, still centered on domestic aerospace (military and civilian), but now entering the Siemens-led gas-turbine chain, and in future nuclear reactor supply chain. These are all high growth, high entry barrier industries which allows Triangle Defense to diversify its customer base and capture new growth opportunities. Specialized forging is a key industrial sector to pay attention to. If we look at the top three companies in the US, it’s PCC, Howmet Aerospace, and ATI. All of which have been top performers, recovering strongly from Covid bottoms. I believe Triangle is like China’s PCC, developing into a specialized forging conglomerate.

Shared challenges: PCC demonstrates that even the best business models can be affected by aviation downturns, tech-route transitions, and overvaluation.

For Triangle, the speed and profitability of new-business order releases determine whether it can re-rate: C919, gas turbines, space. In short, Triangle Defense can be seen as a “Chinese, high-growth-stage version of PCC.” It is moving along the right path—building a moat, extending the product line, binding core customers—but still needs to prove platform scale and long-term earnings stability. This is the heart of the investment thesis.

Key Risks

Demand/Order volatility: Military and civil aircraft orders rely on national planning and OEM production schedules. Project-execution risk: 1250MN and other major projects require heavy investment; construction and ramp-up might be behind. ~Only 10% of the funds for the blade project have been utilized—probably due to technical issues—although hot-load testing has succeeded. International certification risk: Gas-turbine business requires long, high-standard certification processes. Competition: State-owned players like AVIC Heavy Machinery may continue to expand capacity, putting pressure on pricing and orders. However, Triangle's deep experience, geographic advantage, strong shareholders, and technical leadership-most particularly 1250MN-reduce competitive concern.